Innovative Humanoid Workers Revolutionize Production Processes in BMW Automobile Manufacturing

Innovative Humanoid Workers Revolutionize Production Processes in BMW Automobile Manufacturing

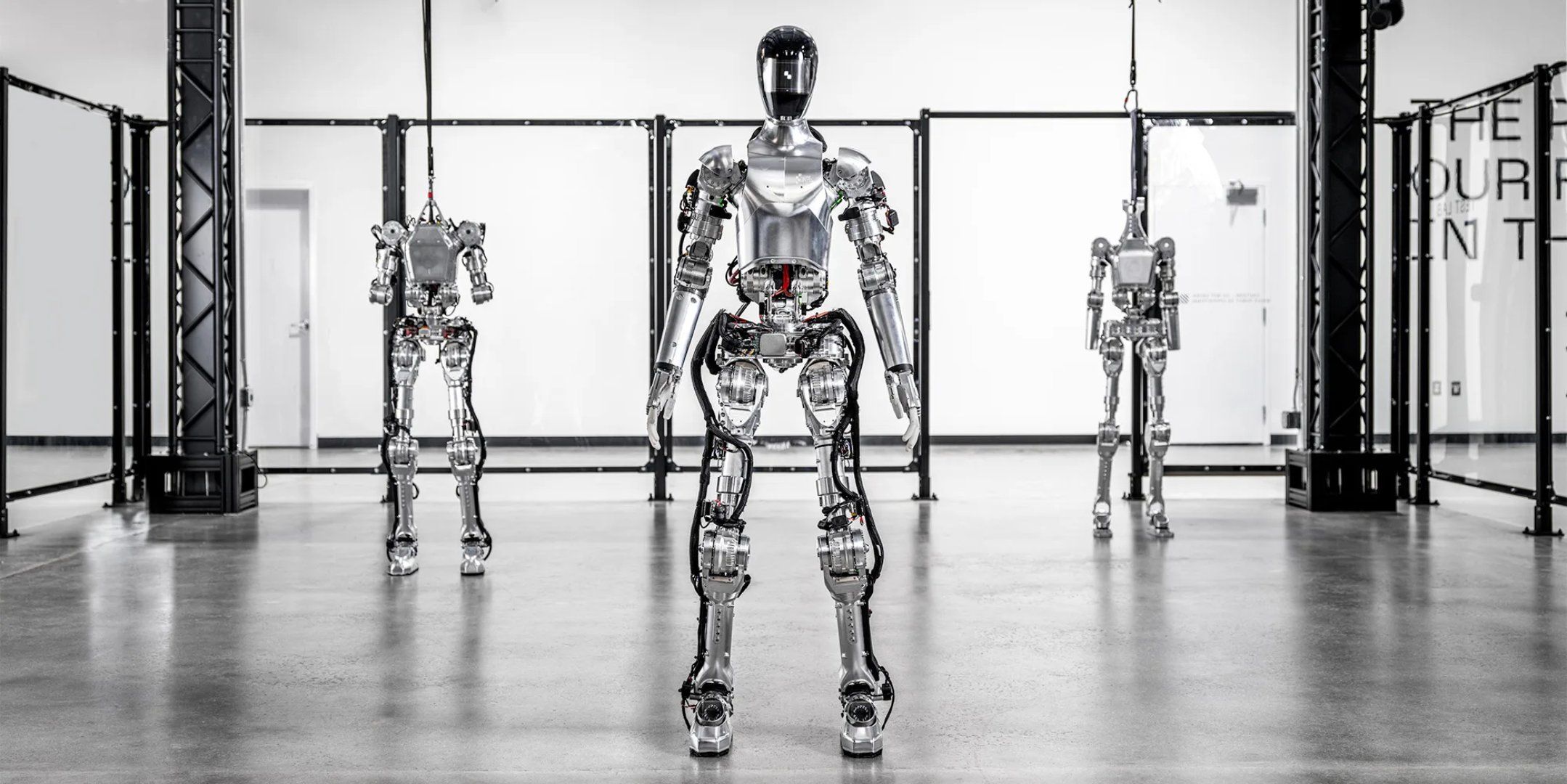

Six months after BMW signed a deal with robotics startup Figure AI, the Figure 01 bipedal humanoid robots are being tested at BMW’s Spartanburg, South Carolina production facility. Figure’s latest progress report shows how the robots could help in manufacturing jobs.

Figure AI and BMW signed a commercial partnership agreement in January that first saw Figure identify potential use cases for their general-purpose robots in automotive production, then begin staged roll-outs of the autonomous machines in BMW’s manufacturing facility in Spartanburg, South Carolina. “Single-purpose robotics have saturated the commercial market for decades, but the potential of general purpose robotics is untapped. Figure’s robots will enable companies to increase productivity, reduce costs, and create a safer and more consistent environment,” Brett Adcock, Founder and CEO of Figure, said in a January press release, by performing the tedious and dangerous jobs that humans don’t want to do.

The Spartanburg plant is the largest automotive exporter in the US, employing 11,000 people on a campus spanning 8 million square-feet. Workers there assemble the X3, X4, X5, X6, X7, and XM Sports Activity Vehicles. Over the past 30 years, more than 6.3 million BMW vehicles have rolled off of its assembly lines. The Figure 01 robots stand five and a half feet tall, weigh 132 pounds, and can carry up to 44 pounds of material at a time. They can walk at speeds up to 2.7 MPH and can operate for up to five hours before their batteries need recharging.

Figure’s robots were first tasked with moving bins and boxes throughout the plant’s body shop, showing their capabilities at grasping complex shapes, navigating and avoiding obstacles, and placing parts with precision. As their training and testing proceed over the next 12 to 24 months, their responsibilities are expected to expand to include performing sheet metal work and warehouse operations.

Figure isn’t alone in its efforts to bring robots to the factory floor. Earlier this month, Agility Robotics began testing its Digit robots at a Spanx factory in Georgia . Tesla continues to develop its Optimus robot and expects to begin production by the end of next year , though Tesla is famous for not meeting its announced goals. Remember when the Cybertruck was supposed to cost $40,000 ?

Source: Figure , YouTube (Figure)

Also read:

- [Updated] Perfect Blueprint for Installing WM6 Version 6.0

- A New Age of Games? Debate the Best VR Headsets Today for 2024

- Best Practices for Configuring and Measuring FB Instream Ads for 2024

- Fun on a Budget – Meme Creator’s Handbook

- How to Downgrade Apple iPhone 14 to the Previous iOS System Version? | Dr.fone

- How to Reset OnePlus Nord CE 3 Lite 5G without Losing Data | Dr.fone

- How to Reset Tecno Pop 8 Without the Home Button | Dr.fone

- In 2024, Does Life360 Notify When You Log Out On Xiaomi Redmi Note 12 5G? | Dr.fone

- Repair Video Tool - Repair all your damaged video files of Lenovo ThinkPhone on Windows

- Reviving the Rumors: HomeOS Spotted Anew as Part of Latest Apple tvOS Developer Preview - What We Know So Far

- Step-by-Step Tutorial on Recording Streaming Content via VLC Software & Exploring Comparable Substitutes

- The way to get back lost call history from Tecno Pova 5 Pro

- Undelete lost photos from Honor 70 Lite 5G.

- Title: Innovative Humanoid Workers Revolutionize Production Processes in BMW Automobile Manufacturing

- Author: Ian

- Created at : 2025-02-15 21:11:04

- Updated at : 2025-02-19 20:51:44

- Link: https://techidaily.com/innovative-humanoid-workers-revolutionize-production-processes-in-bmw-automobile-manufacturing/

- License: This work is licensed under CC BY-NC-SA 4.0.